Components Affecting Variety

The following is usually a listing in the facts important to help in generating a coupling choice. Not all of these objects will come into play in all choice processes. These things consist of, but will not be limited to:

Application associated:

Application facts

Form of motor and driven tools

Motor horsepower or KW

Operating/coupling pace

Shaft sizes and separation

Room and dimension constraints

Atmosphere (temperature, chemical substances, etc)

Balance requirements

Particular modifications

Measures In Deciding on A Gear Coupling

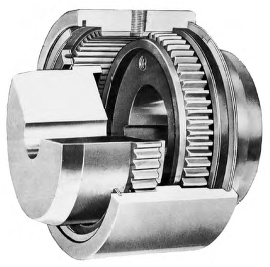

Refer to the gear coupling specifications charts displayed with every form of coupling throughout the Gear Coupling Solutions segment of this catalog. The photographs and charts provide visualization, specifications, and dimensional data for its wide variety of gear coupling solutions. Ordinarily begin with an F Style flanged gear coupling or possibly a C Variety  steady sleeve gear coupling (page G-16) and proceed from there.

steady sleeve gear coupling (page G-16) and proceed from there.

Stage 1: Critique the gear coupling series and style as picked to be sure the selection

meets application demands.

Stage 2: Ascertain the nominal application torque in in-lbs through the use of the following formula:

Application Torque ( in-lb ) = (HP x 63025)/RPM

Or Nm = (KW x 9550)/RPM

Phase three: Review the Application Service Issue chart for that support element variety related using the application wherever this coupling is going to be made use of. Multiply the application torque from the application support factor to find out the complete torque expected for the coupling selection.

Stage four: Examine the needed total torque value with all the nominal torque capacity

listed inside the Gear Coupling Selection chart for your sought after coupling form.

Step 5: Test that the optimum bore dimension as well as the maximum RPM from the coupling

kind selected to make sure the coupling will meet these application necessities.

Phase six: Note any specific necessities which include the BSE dimension for floating shaft and spacer types, shear pin torque, slide coupling details, mill motor tapered shaft data, and any other pertinent data.